Agricultural and Biological Research

RNI # 24/103/2012-R1

Research Article - (2022) Volume 38, Issue 4

This work aims to enhance the agro-resources of Benin, in order to reduce post-harvest losses. It consisted of developing a new product, a shandy based on local tchakpalo beer and orange juice. The drink was obtained using a mixing plan of tchakpalo and orange juice. The microbiological, sensory and physico-chemical analyzes were carried out by standard methods. The results proved that all the formulated drinks were of satisfactory microbiological quality. The most popular shandy formula (75% orange juice and 25% lightly fermented tchakpalo) had a yellowish color, a slightly sweet and slightly sour taste and a pleasant aroma. Furthermore, it had a specific gravity of 1.03 ± 0.00; a pH of 5.35 ± 0.07; a titratable acidity of 6.55 ± 0.21 mg/g, a dry matter content of 9.15 ± 0.01%, an ash content of 1.93 ± 0.02%, a Brix degree of 9.75 ± 0.07; a content of tannin, total flavonoids and total phenol, respectively of 37.53 ± 0.04 mgLeuE/mL; 51.31 ± 0.03 mgQE/mL and 18.86 ± 0.02 mg GAE/mL. It then becomes essential to move on to the pilot phase for the promotion of this new product.

Tchakpalo; Analysis; Valorization; Agro-resources

Innovations in food technology are important for business survival in an increasingly demanding consumer environment [1]. In Africa, certain cereals such as maize, millet and sorghum are often transformed into energy-rich drinks, the production of which requires an essential step of alcoholic fermentation [2]. These drinks are known under various names such as ikagage in Rwanda [3], pito or burukutu in Nigeria and Ghana [4], amgba in Cameroon [3], doro or chibuku in Zimbabwe [5], merissa in Sudan [6], mtama in Tanzania [7], bili bili in Chad [8], kaffir in South Africa [9] and tchakpalo in Côte d'Ivoire, Togo and Benin [10-13].

Today, the market for low-alcohol beers has grown due to changing consumer behavior for health or religious reasons. However, these commonly consumed drinks have a relatively low content of vitamins and minerals [14]. It is therefore imperative to improve the nutritional and organoleptic profile of non-alcoholic or low-alcoholic drinks by adding fruit juice to meet consumer expectations. Indeed, non-alcoholic or low-alcoholic drink mixes are in high demand due to their sensory characteristics, functional and nutritional properties [15,16].

Fruits play an important role in human nutrition. They are delicious and are valuable sources of vitamins, minerals and dietary fibers. Fruits also contain pigments, phenolic compounds with antioxidant properties, and other phytochemicals that help prevent cancers, lower cholesterol, and lower blood pressure [17].

Orange (Citrus sinensis) is widely used for juice production due to its high acceptability and high nutritional value. It is a source of citric acid, potassium, amino acids (serine, arginine and proline) and ascorbic acid [16,18]. Orange is also rich in flavanones and flavones, mainly hesperidin, which gives the juice its color and special taste [19]. The objective of this study is to develop a new food product, of good nutritional and functional quality to enhance local agroresources and endogenous technologies.

Sampling and mixing plan

Chemicals used in this study including methanol, distilled water (Aq), n-hexane, Dimethyl Sulfoxide (DMSO), Folin-Ciocalteu (FC) reagent, anhydrous sodium carbonate, Gallic Acid (GA), aluminium trichloride hexahydrate, sodium acetate, DPPH were of AR grade. All the above reagents and Potato Dextrose Agar (PDA), Glucose (Glc) and agar were purchased from Sinopharm Chemical Reagent Beijing Co., Ltd. Standard antibiotic drugs, gentamycin and terbinafine were obtained from Pharmagen, Hefei. Laminar flow cabinet was produced by Stramline Laboratory. Petri plates and glass columns were bought from Hefei Meifeng Chemical Instrument Co. Ltd. Autoclaver was produced by Shanghai ShenAn medical equipment factory. Two types of shandy were produced. These are the shandy obtained from local beer purchased from a producer based in Glazoué (Zone A) (7° 58' 25'' North 2° 14' 24'' East, large production area of tchakpako in Benin) and shandy obtained from tchakpalo produced in the technological hall of the Schools of Science and Techniques for Preservation and Processing of Agricultural Products (ESTCTPA-Sakété) (Zone B, 6° 44′ 11″ north, 2° 39′ 29″ east). Each type of beer has undergone fermentation for 24 hours or 48 hours. These different beer formulas were obtained by following the mixing plan generated in Minitab 16 (Table 1).

| Samples code | Raw material Origin | Duration of fermentation (Days) | Proportion of beer (%) | Proportion of juice (%) | |

|---|---|---|---|---|---|

| A-area | A1 | Glazoué | 1 | 50 | 50 |

| A2 | Glazoué | 1 | 25 | 75 | |

| A3 | Glazoué | 1 | 75 | 25 | |

| A1’ | Glazoué | 2 | 50 | 50 | |

| A2’ | Glazoué | 2 | 25 | 75 | |

| A3’ | Glazoué | 2 | 75 | 25 | |

| A1’’ | Glazoué | 1 | 100 | 0 | |

| A2’’ | Glazoué | 2 | 100 | 0 | |

| B-area | B1 | ESTCTPA-Sakété | 1 | 50 | 50 |

| B2 | ESTCTPA-Sakété | 1 | 25 | 75 | |

| B3 | ESTCTPA-Sakété | 1 | 75 | 25 | |

| B1’ | ESTCTPA-Sakété | 2 | 50 | 50 | |

| B2’ | ESTCTPA-Sakété | 2 | 25 | 75 | |

| B3’ | ESTCTPA-Sakété | 2 | 75 | 25 | |

| B1’’ | ESTCTPA-Sakété | 1 | 100 | 0 | |

| B2’’ | ESTCTPA-Sakété | 2 | 100 | 0 | |

| C | Sakété | - | 0 | 100 |

Note: Zone A: Tchakpalo from Glazoué, Zone B: Tchakpalo produced at ESTCTPA-Sakété, A1: 50% orange juice-50% Lightly fermented Tchakpalo (Glazoué), B1: 50% orange juice-50% Lightly fermented Tchakpalo (ESTCTPA), A2: 75% orange juice-25% lightly fermented Tchakpalo (Glazoué), B2: 75% orange juice-25% lightly fermented Tchakpalo (ESTCTPA), A3: 25% orange juice orange-75% slightly fermented Tchakpalo (Glazoué), B3: 25% orange juice-75% slightly fermented Tchakpalo (ESTCTPA), A1': 50% orange juice-50% highly fermented Tchakpalo(Glazoué), B1': 50% orange juice-50% very fermented Tchakpalo (Calavi), A2': 75% orange juice-25% very fermented Tchakpalo (Glazoué), B2': 75% orange juice-25% very fermented Tchakpalo fermented (E ESTCTPA), A1'': Lightly fermented Tchakpalo control (Glazoué), B1'': Lightly fermented Tchakpalo control (ESTCTPA), A2'': Very fermented Tchakpalo control (Glazoué), B2'': Very fermented Tchakpalo control (Calavi), C: Control orange juice.

Table 1: Mixing plan of tchakpalo and orange juice for the shandy production.

Shandy manufacturing process

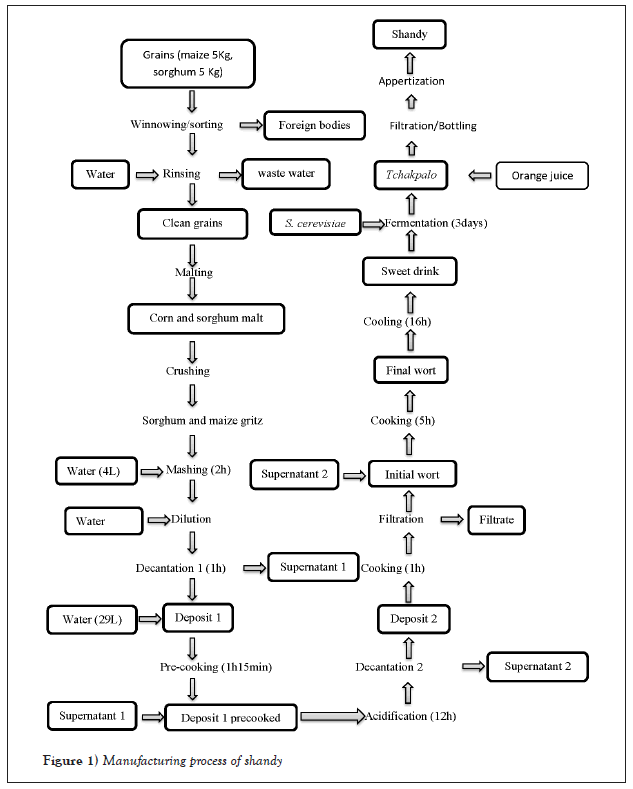

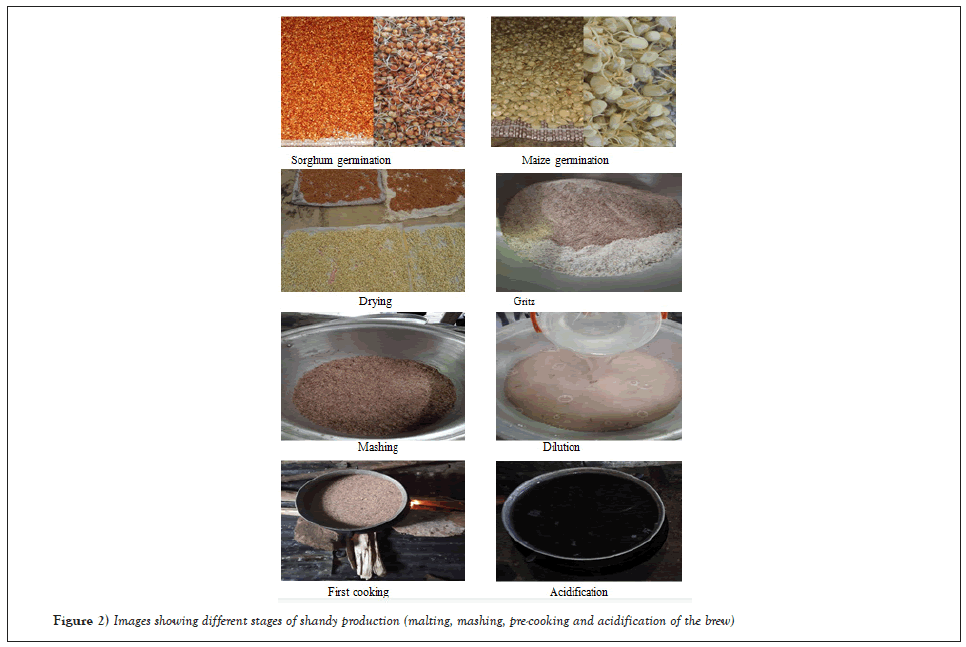

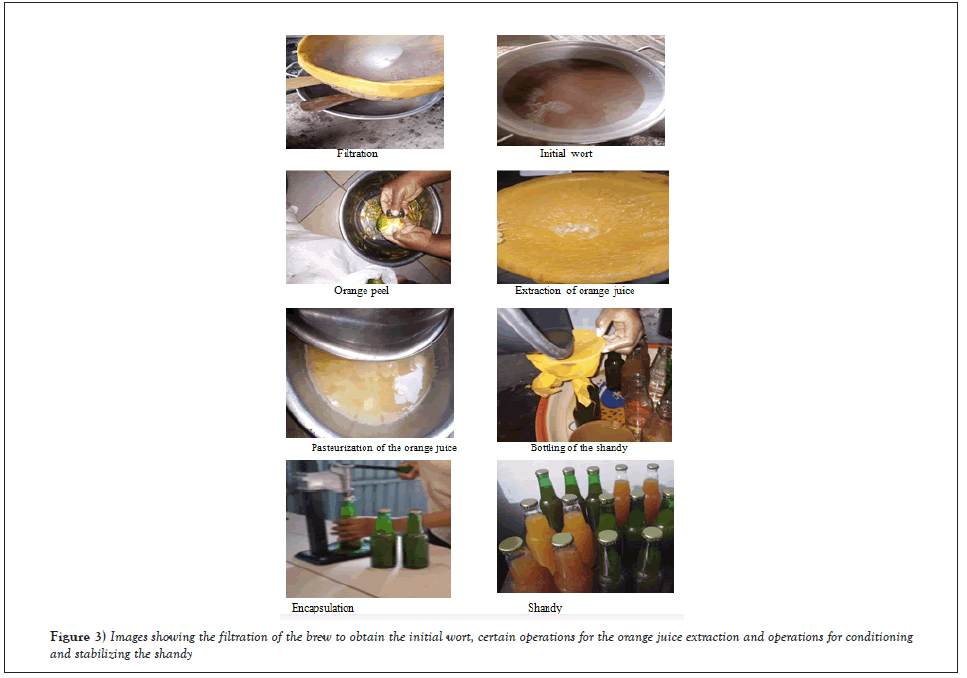

The shandy production was made in three main stages: A first step was the local beer tchakpalo production, a second, in the production of orange juice and a third, in the shandy production by mixing the local beer and orange juice. (Figure 1,2,3).

Figure 1: Manufacturing process of shandy.

Figure 2: Images showing different stages of shandy production (malting, mashing, pre-cooking and acidification of the brew).

Figure 3: Images showing the filtration of the brew to obtain the initial wort, certain operations for the orange juice extraction and operations for conditioning and stabilizing the shandy.

Shandy quality assessment

As a first step, all the samples produced were subjected to a microbiological evaluation. Once the satisfactory hygienic quality was proven, the organoleptic quality was then assessed. This allowed identifying the shandy formula most appreciated by tasters. Finally, the physico-chemical and functional analyzes were perfomed on the control drinks and on the most appreciated shandy formula.

Microbiological characterization of samples

Standard methods were used to determine the total mesophilic aerobic flora by inoculation on Plate Count Agar (PCA) medium and incubation at 30°C for 24-48 h [20], total and thermotolerant coliforms [21,22] on Violet Red Bile Lactose (VRBL) medium with incubation at 30 and 44°C respectively for 24 hours, yeasts and molds on Sabouraud medium with chloramphenicol [23] then incubation at 25°C for 3 to 5 days.

Organoleptic analyzes

The organoleptic analysis consisted in carrying out a preference test by classification. The panel was made up of 30 untrained people, recruited on the basis of their availability and having no aversion to the product. The samples were presented randomly to each panelist following a blind distribution (coded samples). The sensory criteria evaluated are: color, sweet taste, acid taste and aroma.

Physico-chemical analyzes

The pH was measured with a pH meter (HANNA HI 98129) while the Brix degree were determined using a portable refractometer (ATAGO, Japan). The acidity expressed as a percentage of citric acid per unit volume was determined by assay with 0.1 mol/L sodium hydroxide in the presence of phenolphthalein as a colored indicator [24]. On the other hand the dry matter content was determined according to methods [25]. The relative density at 20°C of shandy was determined by the method described by [26]. For the determination of ash content, the samples were incinerated at (550 ± 15) °C in a muffle furnace.

Dosage of the functional compounds

Total phenol content: The method used consists in mixing 3 mL of distilled water with 50 µL of extract then 250 µL of Folin-Ciocalteu reagent and 750 µL of 7% Na2CO3. After 8 min, add 950 µL of distilled water and after two hours measure the absorbance at 765 nm against a blank without extract taken as a reference. The quantification of phenols was determined by the calibration curve produced with gallic acid at different concentrations under the same conditions as the sample. The results were expressed in mg gallic acid equivalent per mL of shandy (mgGAE/mL) [27,28].

Evaluation of the total flavonoid content: The total flavonoid content was determined by the AlCl3 method. To 1 mL of shandy, 1 mL of aluminum chloride (2%) was added. The whole was shaken and then incubated for 10 minutes in the dark. The absorbance reading was taken at 455 nm. The flavonoid concentration was determined by referring to a calibration curve made with quercetin. The results are expressed in milligrams of quercetin equivalent per mL of shandy (mgQE/mL) [29].

Dosage of tannin: The condensed tannins were assayed by the Butanol-HCl method [30]. The reaction medium was composed of 0.5 ml of the drink, 3 ml of butanol-HCl (95/5) and 0.1 ml of a ferric solution (2% ferric ammonium sulphate, diluted in 2 N HCl). The samples were incubated in a boiling water bath for 60 min. The absorbance was measured at 550 nm and the results are expressed in equivalent leucocyanidins, according to the following formula:

T (mgLeuE/mL) = (A550 nm × 78.26 × DF [30].

A: Absorbance recorded at 550 nm

DF: Dilution Factor

Statistical analysis: The data generated during this study was described and organized in the form of tables and histograms using the Microsoft Excel 2010. The comparison of the means was performed using an analysis of variance (ANOVA) in Minitab 16. Significance of difference was recorded at 0.05 levels.

Microbiological characteristics of the coolers produced

The analysis of Table 2 shows that the total flora was counted at levels greater than or equal to the minimum tolerance value in ten (10) samples (A1', A2, A2', A3', A1'', A2' ', B1, B1', B2 and B3). The counted values varied between 102 CFU/mL ± 0 to 950 × 103 ± 1.06 CFU/mL. In the other samples, this flora was counted at levels below 102 CFU/mL. Total coliforms were counted in five (5) samples (A2', A2'', B1', B2'', and C) and ranged from 10 ± 0 to 70 ± 0 CFU/mL while thermotolerant coliforms and yeasts were absent in all samples. Finally, molds were counted at levels greater than or equal to the minimum reference value (between 10 ± 0 and 1655 × 103 ± 2.33 CFU/mL) in 13 samples (Table 2).

| Samples/Parameters | Total Mesophilic Aerobic Flora (CFU/mL) | Total coliforms (CFU/mL) | Thermotolerant coliforms (CFU/mL) | Yeasts (CFU/mL) | Molds | |

|---|---|---|---|---|---|---|

| (CFU/mL) | ||||||

| A-area | A1 | <102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 60 ± 0 |

| A1' | 102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 50 ± 0 | |

| A2 | 2 × 102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 10 ± 0 | |

| A2' | 950 × 103 ± 1.06 | 70 ± 0 | <10 ± 0 | <10 ± 0 | 40 ± 0 | |

| A3 | <102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | |

| A3' | 750 × 102 ± 4.95 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 55 ± 7.07 | |

| A1'' | 2 × 102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 10 ± 0 | |

| A2'' | 102 ± 0 | 10 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | |

| B-area | B1 | 550 × 102 ± 2.12 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 1655 × 103 ± 2.33 |

| B1' | 35 × 102 ± 7.07 | 20 ± 0 | <10 ± 0 | <10 ± 0 | 35 × 101 ± 2.12 | |

| B2 | 25 × 102 ± 7.07 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 30 ± 0 | |

| B2' | <102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 10 ± 0 | |

| B3 | 102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 35 × 101 ± 3.54 | |

| B3' | <102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | 70 ± 0 | |

| B1'' | <102 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | |

| B2'' | <102 ± 0 | 10 ± 0 | <10 ± 0 | <10 ± 0 | 70 ± 0 | |

| C | <102 ± 0 | 10 ± 0 | <10 ± 0 | <10 ± 0 | <10 ± 0 | |

| Normative criteria | <102 | <10 | <10 | <10 | <10 | |

Note: Zone A: Tchakpalo from Glazoué, Zone B: Tchakpalo produced at ESTCTPA-Sakété, A1: 50% orange juice-50% Lightly fermented Tchakpalo (Glazoué), B1: 50% orange juice-50% Lightly fermented Tchakpalo (ESTCTPA), A2: 75% orange juice-25% lightly fermented Tchakpalo (Glazoué), B2: 75% orange juice-25% lightly fermented Tchakpalo (ESTCTPA), A3: 25% orange juice orange-75% slightly fermented Tchakpalo (Glazoué), B3: 25% orange juice-75% slightly fermented Tchakpalo (ESTCTPA), A1': 50% orange juice-50% highly fermented Tchakpalo (Glazoué), B1' : 50% orange juice-50% very fermented Tchakpalo (Calavi), A2': 75% orange juice-25% very fermented Tchakpalo (Glazoué), B2': 75% orange juice-25% very fermented Tchakpalo fermented (E ESTCTPA), A1'': Lightly fermented Tchakpalo control (Glazoué), B1'': Lightly fermented Tchakpalo control (ESTCTPA), A2'': Very fermented Tchakpalo control (Glazoué), B2'': Very fermented Tchakpalo control (Calavi), C: Control orange juice.

Table 2: Microbiological characteristics of samples.

Organoleptic characteristics of the shandy produced

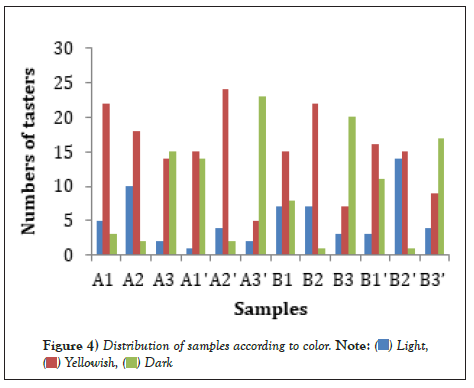

The sample that presented a lighter appearance was B2 (25% orange juice-75% lightly fermented tchakpalo. For the majority of tasters (80%), the A2 sample was yellowish while the sample A3' was the darkest in appearance (Figure 4).

Figure 4: Distribution of samples according to color.

.

.

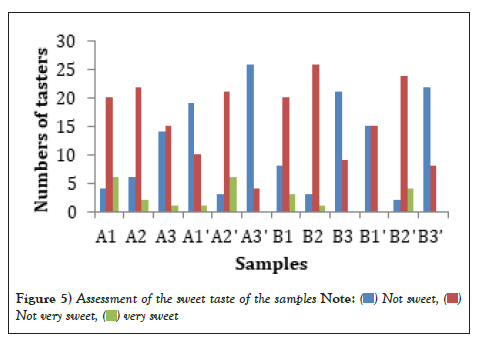

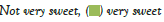

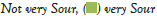

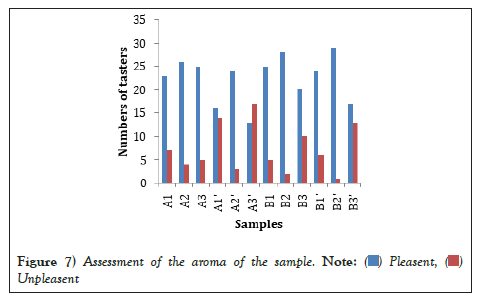

For 86.66% of the tasters, the B2 sample was not very sweet. A3' was not sweet at all while samples A1 and A2' were the sweetest (Figure 5). Regarding the acid taste, samples A1 and B2' (70% tasters), B2 (63% tasters), B1 and A3 (60% tasters respectively) were really not acidic. On the other hand, samples B3 (60% tasters) and B1' (46.66%) had a very acid taste according to the members of the tasting panel (Figure 6). Moreover, for 96.66% and 93.33% of the tasters, the aroma of sample B2' and B2 were pleasant respectively, while 56.66% of the tasters found that the aroma of sample A3' was unpleasant (Figure 7). Finally, to the question "which of the samples did you like the most?" 50% of the tasters preferred the B2 sample (Figure 8).

Figure 5: Assessment of the sweet taste of the samples.

.

.

Figure 6: Assessment of the acid taste of the samples.

.

.

Figure 7: Assessment of the aroma of the sample.

.

.

Figure 8: Global appreciation.Zone A: tchakpalo from Glazoué, Zone B: tchakpalo produced at ESTCTPA-Sakété, A1: 50% orange juice - 50% Lightly fermented tchakpalo (Glazoué), B1: 50% orange juice-50% Lightly fermented tchakpalo (ESTCTPA), A2: 75% orange juice-25% lightly fermented tchakpalo (Glazoué), B2: 75% orange juice-25% lightly fermented tchakpalo (ESTCTPA), A3: 25% orange juice orange-75% slightly fermented tchakpalo (Glazoué), B3: 25% orange juice-75% slightly fermented tchakpalo (ESTCTPA), A1': 50% orange juice-50% highly fermented tchakpalo (Glazoué), B1' : 50% orange juice-50% very fermented tchakpalo (Calavi), A2': 75% orange juice-25% very fermented tchakpalo (Glazoué), B2': 75% orange juice-25% very fermented tchakpalo fermented (E ESTCTPA), A1'': Lightly fermented tchakpalo control (Glazoué), B1'': Lightly fermented tchakpalo control (ESTCTPA), A2'': Very fermented tchakpalo control (Glazoué), B2'': Very fermented tchakpalo control (Calavi), C: Control orange juice.

Physico-chemical characteristics of the samples

The physico-chemical analyzes were performed on the most popular product and its constituents (tchakpalo and orange juice used as controls). This is sample B2 (25% orange juice-75% slightly fermented tchakpalo and produced at the ESTCTPA application unit). The shandy showed values intermediate between those of the controls with regard to pH, brix, and dry matter. Orange juice had the highest pH (5.58 ± 0.01), followed by shandy (5.35 ± 0.07) and tchakpalo (4.93 ± 0.007). The local beer tchakpalo presented the highest brix degree, titratable acidity and dry matter content (13.80 ± 0.14%; 6.35 ± 0.071% and 14.21 ± 0.02%), followed by the shandy (9.75 ± 0.07%; 6.55 ± 0.21% and 9.15 ± 0.01%) and orange juice (8.00 ± 0.14%; 4.49 ± 0.01% and 6.46 ± 0.01%) respectively. On the other hand, for the ash content, orange juice presented the highest value (1.96% ± 0.02), followed by shandy (1.93% ± 0.02) and tchakpalo (0.29% ± 0.01). Finally, the tchakpalo, the orange juice and the shandy seemed to present the same densities (1.059 ± 0.00; 1.03 ± 0.00 and 1.03 ± 0.00) respectively (Table 3).

| Samples/Parameters | pH | Brix degree | Titratable acidity (%) | Dry matter content (%) | Ash content (%) | Density |

|---|---|---|---|---|---|---|

| Tchakpalo | 4.93 ± 0.007b | 13.80 ± 0.14a | 6.35 ± 0.071a | 14.21 ± 0.02a | 0.29 ± 0.01b | 1.059 ± 0.00a |

| Shandy | 5.35 ± 0.07a | 9.75 ± 0.07b | 6.55 ± 0.21a | 9.15 ± 0.01b | 1.93 ± 0.02a | 1.03 ± 0.00a |

| Orange juice | 5.58 ± 0.01a | 8.00 ± 0.14c | 4.49 ± 0.01b | 6.46 ± 0.01c | 1.96 ± 0.02b | 1.03 ± 0.00a |

| P-value | 0.001 | 0 | 0.001 | 0 | 0 | 0 |

| Codex Standard Stan 247-2005 | <4 | 11.2-11.8 | - | - | - | >1.045 |

Note: Means with the same letters (a, b or c) in the same column are not significantly different (p<5%).

Table 3: Physico-chemical characteristics of the samples.

Content of total phenols, total flavonoids and tannin

The shandy produced presented intermediate values between those of tchakpalo and orange juice. Orange juice had the highest phenol content (19.93 ± 0.042 µg GAE/mL) while tchakpalo had the highest total flavonoid and tannin content (132.94 ± 0.04 mg QE/mL) and (32.86 ± 0.01 mg LeuE/mL) respectively (Table 4). For all parameters, the observed differences were significantly different at the 5% level.

| Samples/Parameters | Total phenols (mg GAE /mL) | Flavonoids (mgQE /mL) | Tannins (mgLeuE/mL) |

|---|---|---|---|

| Tchakpalo | 19.93 ± 0.042a | 132.94 ± 0.04a | 32.86 ± 0.01a |

| Shandy | 18.86 ± 0.02b | 51.31 ± 0.03b | 37.53 ± 0.04b |

| Orange juice | 21.53 ± 0.02c | 19.97 ± 0.01c | 38.59 ± 0.01c |

| P-value | 0 | 0 | 0 |

Note: Means with the same letters (a, b or c) in the same column are not significantly different (p<5%).

Table 4: Samples content in functional compounds.

In this study, we produced tchakpalo from its original manufacturing process and the sensory characteristics of the drink were improved by incorporating orange juice. Indeed, to improve the nutritional intake of the shandy, it was preferable to mix the beer with fruit juice rather than carbonated or flavored drinks whose nutritional values are low. Fruit juices are generally a good source of minerals, vitamins, trace elements and antioxidant [31]. Following the sensory analyzes, it was noticed that the B2 formula (75% orange juice and 25% slightly fermented tchakpalo) was the best appreciated by the tasters. This is the formula that received the highest dose of juice. This result could be explained by the fact that the tasters were more accustomed to consuming orange juice. In addition, this formula was obtained by light fermentation of local beer. During the fermentation of tchakpalo, microbial proliferation makes the drink sour as a result of extensive lactic fermentation. This fermentation is superimposed by an alcoholic fermentation. These phenomena significantly affect the sensory quality of tchakpalo and could justify the choice of tasters [32]. In addition, this is good news for the promotion of the new product because alcohol consumption can harm both health and social relationships. The nature and intensity of these effects depend on both the total amount of alcohol consumed over time and drinking habits. The dependence on alcohol and the chronic illnesses (gastric ulcers, feminization, impotence, stomach hemorrhage, etc.) that it causes attest that the consumption of alcohol can lead to deterioration in the quality of life and premature death [33].

Moreover, for the majority of the physicochemical and functional parameters evaluated, the shandy produced presented intermediate values between those of tchakpalo and orange juice. Thus, the low levels of total phenols and tannin of tchakpalo were compensated by orange juice while the flavonoid content of orange juice was improved by tchakpalo. The shandy therefore has an optimized composition.

Beer and fruit juices have health benefits, in particular thanks to their mineral and phenolic compound content. Most phenolic compounds exhibit antioxidant properties that are largely. Indeed, in recent years, several studies have highlighted the health benefits of phenols, and special attention has been paid to their beneficial effects against cardiovascular disease, the leading cause of death in the world today [34-37]. Epidemiological observations suggesting an inverse correlation between foods containing phenols consumption and the incidence of cardiovascular diseases have been well established [34-38]. Phenolic acids and flavonoids, although are not essential for survival, may provide protection against a number of chronic diseases over the long term consumption. The phenolic acids potentially involved in these beneficial effects are gallic acid, hydroxycinnamates including coumaric acid, caffeic acid, and derivatives such as chlorogenic acid [39,40]. Furthermore, it is likely that various phenols, including flavonoids, act similarly to dietary antioxidant. Phenols have antioxidant activity and, based on their antioxidant function, these compounds possess anti-atherosclerotic, anti-inflammatory, antitumor, antithrombotic, anti-osteoporosis, and antiviral activities [40,41]. Finally, flavonoids may protect vitamin E in lipid oxidation by being oxidized themselves in preference to vitamin E or by delaying the initiation of lipid peroxidation. Also, flavonoids may inhibit LDL oxidation by scavenging superoxide anions, hydroxyl radicals, or lipid peroxyl radicals. Alternatively, flavonoids may chemically modify LDL and such modification results in LDL being less susceptible to oxidation [42].

In this study, we have developed a technology for producing a shandy from the local beer tchakpalo and orange juice. This new product, obtained by a mixture of 75% orange juice and 25% low alcoholic tchakpalo had acceptable microbiological quality, a yellowish color, a slightly sweet, slightly acid taste and a pleasant aroma. In addition, the mixture of tchakpalo and orange juice allowed obtaining a drink with optimized functional characteristics. This new product will certainly allowed finding other markets for the consumption of the local drink.

There is no conflict of interest in the study.

The authors thank their respective laboratories for technical support.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Konfo CTR, Koudoro AY, Dèdéhou ESCA, et al. Formulation and quality assessment of a shandy drink based on local beer tchakpalo and orange juice in Benin. AGBIR.2022; 38(4):314-320.

Received: 22-Jun-2022, Manuscript No. AGBIR-22-67320; , Pre QC No. AGBIR-22-67320 (PQ); Editor assigned: 27-Jun-2022, Pre QC No. AGBIR-22-67320 (PQ); Reviewed: 11-Jul-2022, QC No. AGBIR-22-67320; Revised: 18-Jul-2022, Manuscript No. AGBIR-22-67320 (R); Published: 25-Jul-2022, DOI: 10.35248/0970-1907.22.38.314-320

Copyright: This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http:// creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.