Agricultural and Biological Research

RNI # 24/103/2012-R1

Research Article - (2023) Volume 39, Issue 3

The generation of biodegradable solid waste and wastewaters is characteristic of all abattoirs including the Lira Municipality Abattoir (LMA) in northern Uganda. The wastes discharged from LMA, contain reasonable amounts of paunch manure (fresh rumen contents), cow dung, diluted blood, urine, loose meat as well as leachate. The lack of a properly designed abattoir in Lira municipality needed to manage and handle the waste has resulted in the discharge of the waste into the environment, leading to pollution of water sources, outbreaks of diseases, and production of unfavorable odors. The objective of this study was to investigate the biogas potential of the LMA biodegradable solid wastes in different mix ratios at ambient temperatures. Measurement at the point of generation method was used to quantify the waste. Representative samples were characterized for biogas potential. Four treatments with varying ratios of the different wastes replicated three times were anaerobically digested in 1500 mL batch digesters with a working volume of 1300 mL. On average 2,597 L, 40 kg and 502 kg of wastewater, cow dung and paunch manure respectively were produced from LMA. The treatment combination of 10% cow dung, 70% paunch manure and 20% leachate produced the highest biogas with the shortest lag phase. However, this combination had the least methane content, among all other combinations tested.

Abattoir waste; Anaerobic digestion; Biogas production; Ambient temperature; Methane

According to Vinnari [1], there is an increasing demand for meat in the world which has led to increased establishments of abattoirs. Within a series of processes, abattoirs generate vast amounts of different solid wastes and wastewaters [2]. Approximately, 20 to 50% of the weight of the animal is not suitable for human consumption [3] thus a lot of by-products are produced such as; paunch, fat and, grease, undigested food, diluted blood, suspended material, urine, loose meat, soluble proteins, excrement among others.

However, many abattoirs in the developing countries are not designed to manage their wastes properly such as; paunch manure (fresh rumen contents), cow dung, and leachate For example, the Lira municipality abattoir, located in the Railways division, in Northern Uganda, is the only one in the municipality, operating beyond the designed capacity of 100 cows slaughtered instead of 60 daily. This abattoir produces vast amounts of biodegradable wastes that end up in open places and nearby water bodies, as there is no currently organized system for their disposal. These improperly managed wastes from the abattoir pollute the environment, act as breeding places for disease-causing vectors, and create a bad odor. This makes the living conditions within the community and its outskirts unfavorable. However, these wastes can be converted into useful clean energy (biogas) and fertilizer inform of slurry through the anaerobic digestion process since they are organic [4]. According to Mashad et al., [5], biogas technology has helped some countries such as India and China in many ways including income generation, life-style improvements, and cost-saving. Moreover, the conversion of abattoir wastes into clean energy has not been fully tapped in Uganda and it is against this background that this study was conducted. The objective of this study was to investigate the biogas potential from the abattoir wastes in different ratios in Lira district, Northern Uganda.

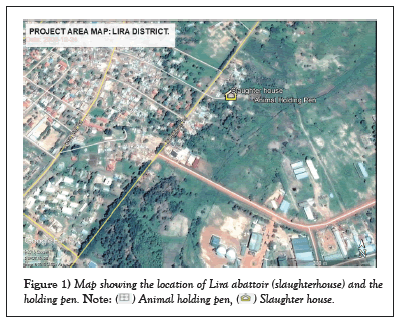

Study area

The study to investigate the biogas potential from the abattoir wastes in different ratios at ambient temperatures was carried out from Lira Municipality (LM), Northern Uganda in Figure 1. Lira Municipality has 4 Divisions, 22 wards, and 64 cells in Figure 1. It covers an area of 7,745 hectares and is surrounded by swamps and buildings Figure 1. Lira Municipality has an altitude of 489678.50 m and a longitude of 249418.12 m respectively.

Figure 1: Map showing the location of Lira abattoir (slaughterhouse) and the

holding pen.

Collection and quantification of biodegradable waste generated from LM slaughterhouse

The biodegradable waste generated from the abattoir was quantified based on the measurement at the point of generation method [4,6]. Pre-weighed calibrated buckets of 16 liter capacity and a digital weighing scale for ten days were used to measure the abattoir wastes. Non-degradable impurities such as stones, plastics and other materials were removed before quantification.

Characterization of the biodegradable abattoir waste for biogas production

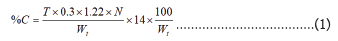

The waste was cleaned by removing the non-biodegradable wastes such as the bones, plastic bags, metals among others, and reduced in size by mashing into a paste. Representative samples were then placed in clean plastic bottles and stored in the refrigerator (at -4°C) before use. Before anaerobic digestion tests, the samples were immediately analyzed on the laboratory scale for Total Solids (TS), Volatile Solids (VS), Fixed Solids (FS), total carbon, total nitrogen, Carbon/Nitrogen ratio (C/N), and pH using standard methods [7]. The aluminum dishes that were used in the laboratory analyses were first ignited at 550°C for one hour in the furnace to remove any volatiles, cooled in the desiccator, and weighed. The samples were heated at 103°C for more than 12 hours and at 550°C for 30 minutes to determine the TS and VS respectively. An electronic digital pH meter was used to determine the pH of the representative samples. The determination of waste organic carbon was based on the Walkley-Black chromic acid wet oxidation method, potassium dichromate as the oxidizing agent with other reagents of sulphuric acid, and ferrous sulfate. The percentage and quantity of carbon were determined from Equations 1and 2, adopted:

Where: N=Normality of K2Cr2O7 solution, T=Volume of FeSO4 used in sample titration (mL) and Wt=Oven-dry sample weight (g).

The Kjeldahl method involving the three steps of digestion, distillation, and titration was used to determine the nitrogen in the biodegradable waste. The reagents that were used included Potassium sulfate, concentrated sulphuric acid, sodium hydroxide, boric acid, and HCl [8]. The percentage and quantity of Nitrogen were determined using Equation 3 and 4.

Where: V is the volume of titrant in ml which is the volume HCl used; Wt is Oven-dry sample weight (g).

The Carbon/Nitrogen (C/N) ratio was then computed based on the results of the carbon and nitrogen. For the reliability of the data and conclusions, three laboratory analyses were involved three replications.

Biochemical methane potential test experimental setup

The 30 day batch anaerobic digestion experiments were conducted to investigate the potential of different abattoir wastes for biogas production at room temperature. The experiments consisted of four treatments with varying ratios of the different abattoir waste Table 1 performed in triplicates in 1500 mL bottles with a working volume of 1300 mL.

| S. No | Treatments | Composition by mass (%) | Ratio |

|---|---|---|---|

| 1 | T1 | 10 cow dung and 90 leachate | 1 CD:9 L |

| 2 | T2 | 50 cow dung and 50 paunch manure | 1 CD:1 PM |

| 3 | T3 | 75 paunch manure and 25 leachate | 3 PM:1 L |

| 4 | T4 | 10 cow dung, 70 paunch manure, and 20 leachate | 1 CD:7 PM:2 L |

Table 1: Experimental design for the batch anaerobic digestion tests.

The inoculum that was used in the study was obtained from an already existing digester being fed with a mixture of food waste and cow dung as the substrates. A blank (inoculum only) was also included to ascertain any biogas produced from the inoculum and correct the biogas production of the experimental treatments. Each treatment received 260 mL of the inoculum. The food to microorganism’s ratio (F/M) was 3 for T1 and 2 for T2, T3, and T4. All the digesters were filled the working volume (1300) with tap water. The substrate-to-water ratio that was used in the study was 1:1 [9]. Furthermore, 0.8 g of sodium carbonate powder (buffer) was added to all the batch digesters to prevent critical pH drop and maintain pH between 6.0-7.0 which, is within the pH range required for biogas production. The retention time used for the study was 30 days under ambient conditions (about 25°C).

The biogas that was obtained was then collected and measured by the water displacement method. To prevent the dissolution of biogas in the water, acidified brine solution was prepared following the method suggested by Misganaw et al., [10]. Since the biogas was insoluble in this solution, a pressure was built-up that provided the driving force for the displacement of the solution. Thus, the displaced brine solution was measured to represent the amount of biogas produced daily. The biogas produced from the digesters was collected by downward delivery of gas, achieved by filling the burettes with brine solution and inverting them in beakers containing the same solution. The reactors were agitated twice a day to make the microorganisms more active during the digestion process for maximum biogas production.

After the 30 days retention time, the gases were left to collect in the digestion bottles where it was delivered to Green Heat for the different gas composition analyses. The percentage of the gases in the biogas was determined by connecting the gas with a cannula to the Geotech portable GA2000 gas analyzer through the inlet port which had an adjuster for connecting the flexible tube. Proportions of methane (CH4), carbon dioxide (CO2), hydrogen sulfide (H2S), and oxygen (O2) were determined and recorded.

Biogas potential data analysis

A modified Gompertz model (Equation 5) was used to simulate the experimental biogas production yield (mL biogas/g substrate), maximum biogas production rate (mL/g substrate per day) as well as the lag phase [11]. The data analysis was performed in Microsoft Excel with the help of its solver tool.

Where: B is the biogas production at time t (mL biogas/g substrate), P is the maximum biogas production (mL biogas/g substrate), Rm is the maximum biogas production rate (mL biogas /g substrate per day), e is exp (1) which is 2.7183, λ is the lag phase (days), t is the time (days).

Quantification of biodegradable waste generated from LM abattoir

For the 10 days of sampling, 2,597 L, 40 kg, and 502 kg of leachate, cow dung (feces and urine that have passed through a cow’s gut), and paunch manure (fresh rumen content) respectively were produced from Lira Municipality Abattoir (LMA) daily Table 2. Moreover, lots of leachates (2,597 L daily) are generated in LMA because lots of water is used for cleaning purposes while slaughtering the animals. As expected, less cow dung is generated compared to paunch manure (rumen contents) because animals are kept in the abattoir for a short time waiting for slaughtering. Generally, more waste was produced on weekends Table 2 than weekdays because most people in Uganda eat meat on weekends only and vegetables on other weekdays since meat is relatively expensive compared to vegetables.

| Daily waste | Leachate (L) | Cow dung (kg) | Paunch manure (kg) |

|---|---|---|---|

| Daily average (overall) | 2,597 | 40 | 502 |

| Daily average (weekends) | 3,033 | 43 | 605 |

| Daily average (weekdays) | 2,306 | 39 | 434 |

| Monthly average (assuming 30 days in a month) | 77,910 | 1,209 | 15,072 |

| Annual average (assuming 365 days in a year) | 9,47,905 | 14,709 | 1,83,376 |

Table 2: Daily waste production in Lira municipality abattoir.

Characterization of the biodegradable slaughterhouse waste for biogas production

Table 3 summarizes the characteristics of the individual abattoir wastes used in this study. The pH of the substrates ranged from 6.8 to 6.9 Table 3 which was within the ideal range of 6.5 to 8.0 for anaerobic digestion. Similar pH values of abattoir wastes have been reported in the literature [12]. The TS of the cow dung and paunch manure ranged from 15 to 19%. Obviously, the TS of the leachate were only 1.9% Table 3 because leachate was mainly composed of diluted blood and wastewater (water used for cleaning while slaughtering the cows) with fewer solids. The VS and fixed solids ranged from 71 to 79, and 21 to 30 respectively Table 3. The findings of this study are in line with the study results of Gebrekidan et al., [13] where the TS and VS of animal manure were found to vary between 16% to 20% and 80% respectively. According to literature reports [13], the %VS of animal waste is usually 80 percent of the TS. The high proportion of VS in the manure substrate depicts that a large fraction of the substrate was biodegradable and could serve as an important feedstock for biogas production [14].

| Waste type | pH | Total solids (%) | Volatile solids % | Fixed solids (%) | Carbon (%) | Nitrogen (%) | C/N ratio |

|---|---|---|---|---|---|---|---|

| Leachate | 6.9 (0.1, 3) | 1.9 (0.5, 3) | 71.3 (15.8, 3) | 28.7 (15.8, 3) | 1.56a (0.02, 3) | 0.59a (0.0, 3) | 2.64 |

| Cow dung | 6.8 (0.1, 3) | 19.3 (1.5, 3) | 73 (3.6, 3) | 30.3 (7.5, 3) | 45.75 (1.33, 3) | 2.62 (16.8, 3) | 17.46 |

| Punch manure | 6.9 (0.1, 3) | 15.7 (1.2, 3) | 78.7 (10.7, 3) | 21.3 (10.7, 3) | 21.96 (1.14, 3) | 1.39 (3.5.8, 3) | 15.8 |

Note: Data represent arithmetic mean of measurements (standard deviation, number of samples), a:unit was g/L.

Table 3: Characterization of the abattoir waste for biogas production.

Furthermore, the C/N ratio for this study ranged from 2.6 to 17.5 Table 3. This was relatively lower than the recommended range for the anaerobic digestion process of 20:1 to 30:1 [15]. Moreover, in a study conducted by Riya et al., [15], the C/N ratio of cow manure was about 16 to 25, while Odekanle et al., [12] reported a ratio of 27.4 for the abattoir waste. Therefore, to achieve the objective of this study, the different abattoir wastes (i.e., leachate, cow dung, and paunch manure) were mixed in varying ratios to improve the C/N ratio. The varying ratios may therefore have been responsible for minimizing the liberation of nitrogen in form of ammonia.

Biochemical methane potential test

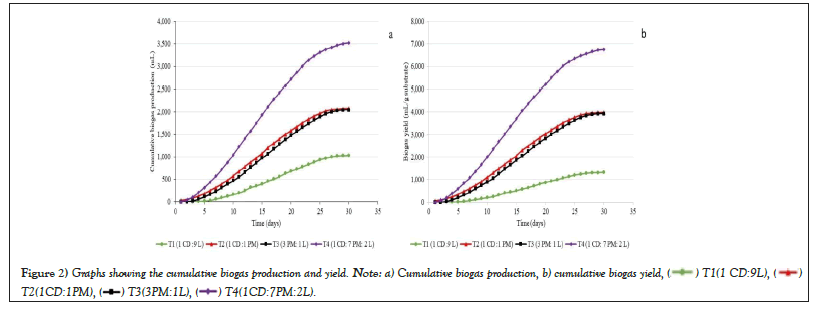

As shown in Figures 2a and 2b, biogas production and yield started at least after 3 days. This is because the microorganisms were still acclimatizing themselves to the new environment all the digesters started gas production on the second day in Figure 2a. From the 8-25th day, there is a significant exponential increase in biogas production due to the rapid utilization of substrates by the microorganisms. Generally, after the 25th day, biogas production became almost constant (stationary growth phase) i.e., the rate of growth and death of microorganisms is equal. The decline in biogas production/death of microorganisms could be probably because of insufficient food to support microbial growth. Furthermore, there could be an accumulation of microbial metabolites such as volatile fatty acids that inhibited the methanogens, responsible for methane production.

Figure 2: Graphs showing the cumulative biogas production and yield. Note: a) Cumulative biogas production, b) cumulative biogas yield,  T2(1CD:1PM),

T2(1CD:1PM),

Biogas production and yield from T4 (10% cow dung, 70% paunch manure, and 20% leachate) were significantly higher than from the other treatments in Figure 2b. This is because T4 had more paunch manure (contents in a cow’s rumen) which is mainly composed of degradable materials as well as active microbial flora that assist the anaerobic digestion process [12]. Furthermore, this mix (10% cow dung, 70% paunch manure, and 20% leachate) could have improved the C/N ratio. Carbon and Nitrogen serve as good starting structural elements for the biosynthesis of carbohydrates and proteins that are essential for microbial growth. On the other hand, T1 (10% cow dung and 90% leachate) had the least biogas production and yield Figure 2b because this treatment had less biodegradable substrate (cow dung) and more water that could not support microbial growth. Moreover, too much water could have created a hypertonic environment (where the osmotic potential of the wastewater was higher than that of the microbial cell cytoplasm) that negatively impacted the growth of microorganisms. From the characterization results, leachate had the least C/N ratio (average of 2.6) hence there could have been a release of a lot of nitrogen in form of ammonia in treatment T1. There was no significant difference in both biogas production and yield between treatments T2 and T3 Figure 2a. The results from the current study Figure 2a are generally comparable with Ahn et al., [16] results that reported 2.5 L (2500 mL) of biogas production from diary manure.

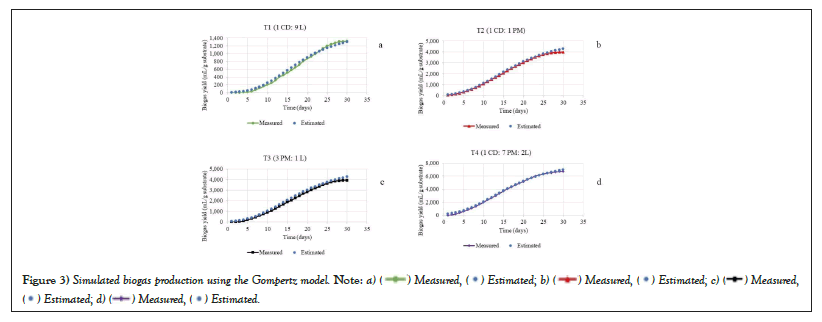

Experimental results from all the treatments tested were well simulated with the modified Gompertz model with an R2 value of more than 0.99 Figures 3a-3d and Table 4. According to the modified Gompertz model, T4 (10% cow dung, 70% paunch manure, and 20% leachate) was the best treatment with the maximum biogas production yield (8000 mL/g substrate), maximum biogas rate (340 mL/g substrate per day), and the shortest lag phase of only 3.9 days Table 4. On the other hand, T1 (10% cow dung and 90% leachate) was still the worst treatment with the least maximum biogas yield, least biogas rate, and the longest lag phase Table 4.

Figure 3: Simulated biogas production using the Gompertz model.

| Treatments | Maximum biogas production, P (mL/ g substrate) | Maximum biogas rate, Rm (mL/ g substrate. d) | Lag phase, λ (days) | R2 |

|---|---|---|---|---|

| T1 (1 CD: 9 L) | 1500 | 70 | 6.8 | 0.99575 |

| T2 (1 CD: 1 PM) | 5000 | 210 | 4.7 | 0.99877 |

| T3 (3 PM: 1 L) | 5000 | 210 | 5.2 | 0.99912 |

| T4 (1 CD: 7 PM: 2 L) | 8000 | 340 | 3.9 | 0.99911 |

Table 4: Gompertz model summary results from all the treatments tested.

Quality of the biogas from the abattoir wastes

The average methane composition of the biogas produced from the abattoir waste at ambient temperatures ranged from 40.6% to 47.3% Table 5 with treatment T3 (75% paunch manure and 25% leachate) and T4 giving the highest and the least percentages of methane respectively. Biogas from all the treatments had other impurities such as CO2 (ranging from 25.2 to 26.1%), O2 (0.3 to 0.5%), and less than 0.1% H2S Table 5. Generally, the methane content of biogas in the current study was slightly lower than reported values in literature probably of the operating conditions that exposed the methanogens to lower levels of oxygen, which is toxic to them.

| Treatments | CH4 (%) | CO2 (%) | O2 (%) | H2S (%) |

|---|---|---|---|---|

| T1 (1CD:9L) | 44.5 (5.5, 20) | 26.1 (3.3, 20) | 0.33 (0.31, 20) | 0.03 (0.011, 20) |

| T2 (1 CD: 1 PM) | 44.1 (3.8, 20) | 25.4 (3.7, 20) | 0.48 (0.33, 20) | 0.037 (0.016, 20) |

| T3 (3 PM: 1 L) | 47.3 (4.3, 20) | 25.6 (5.9, 20) | 0.33 (0.22, 20) | 0.034 (0.017, 20) |

| T4 (1 CD: 7 PM: 2L) | 40.6 (10.7, 20) | 25.2 (3.2, 20) | 0.48 (0.35, 20) | 0.051 (0.025, 20) |

Note: Data represents the arithmetic mean of measurements (standard deviation, number of samples).

Table 5: Biogas composition from the different treatments.

The findings of this study show that there is enough biodegradable waste (2,597 L, 40 kg, and 502 kg of wastewater, cow dung, and paunch manure respectively) generated in Lira Municipality abattoir with high potential for biogas production. The findings show that it is possible to produce biogas production at ambient, uncontrolled temperatures. The treatment combination of 10% cow dung, 70% paunch manure, and 20% leachate produced the highest biogas with the shortest lag phase. However, this combination had the least methane content, among all other combinations tested.

Isaac Ekwar performed the experiments, Chrish Kavuma and Resty Nabaterega wrote the first manuscript under the guidance of Joseph Lwanyaga and Paul Serumaga.

I acknowledge the Faculty of Engineering Busitema University for the support rendered to this research.

The data used in this manuscript is available and can be availed by the corresponding author on request.

There are no competing interests among authors.

The funding was done by the researcher themselves with the help of the Faculty of Engineering at Busitema University.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Kavuma C, Ekwar I, Nabaterega R, et al. Biogas potential from abattoir wastes in different ratios at ambient temperatures: A case of lira municipality of Northern Uganda. AGBIR.2023;39(3): 547-551.

Received: 22-Feb-2023, Manuscript No. AGBIR-23-89888; , Pre QC No. AGBIR-23-89888 (PQ); Editor assigned: 09-Mar-2023, Pre QC No. AGBIR-23-89888 (PQ); Reviewed: 03-Apr-2023, QC No. AGBIR-23-89888; Revised: 18-Apr-2023, Manuscript No. AGBIR-23-89888 (R); Published: 01-May-2023, DOI: 10.35248/0970-1907.23.39.547-551

Copyright: This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http:// creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.